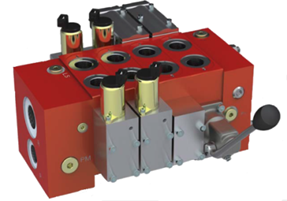

Proportional Directional Valves

Bucher Series LVS

With the LVS hydraulic valve, designers can now create those mobile machine control systems that previously have been difficult to master. Its consistant design as a system of valve modules means exceptional adaptability.

The integral auxiliary functions and high power density make the LVS not only a highly adaptable modular valve, but also a very compact one. LVS valve blocks can be configured for both fixed and variable displacement pumps.

Advantages

- Savings in energy costs due to low pressure losses

- Reliable supply of flow, because the proportional flow sharing principle ensures that all functions can be operated even in the under supply zone.

- Oscillation stable even in critical applications, preventing machine breakdowns

- One valve block solution for all pump systems

Technical Data

|

|

|

LVS08 |

LVS12 |

|

Nominal flow rate in the block, max. |

l/min |

180 |

180 |

|

Actuator flow rate, max. |

l/min |

50 |

180 |

|

Inlet pressure, P |

bar |

250 |

350 |

|

Actuator Pressure, A + B |

bar |

280 |

380 |

|

Tank line pressure (max.) |

bar |

200 |

40 (opt. 200) |

| Viscosity range |

mm²/s (cSt) |

10 - 380 |

10 - 380 |

|

Voltage |

V DC |

12 or 24 |

12 or 24 |

Types of functions

Inlet sections

- pressure relief

- 3-way pressure compensator

- priority valve

Directional sections

- direct acting solenoid, ON/OFF

- direct acting solenoid, proportional

- hydraulically operated

- two-stage, electro-hydraulic operated

- flow control functions

- pressure compensator

- secondary PR and make up valve

- seat valve

- manual over-ride

- lift/lower valve

Email: sales@hsac.co.nz